Monday, February 19 2024

Gold is generally considered a time-tested safe-haven asset, the price of which has historically held up well in times For those of us afflicted with gold fever and who enjoy prospecting and mining as a hobby, the price of gold doesn't make much difference. Most small-scale prospectors seem to get much more pleasure from the process of finding the gold rather than selling it. It's the thrill of the hunt! And, of course, all the great memories you make. Plus, it's just plain old fun buying a new highbanker or gold wheel. Even if you have no intention of selling any of the nuggets or fine gold you recover, you still might be wondering where the price is going from here. Whether or not gold has reached its peak is a point of contention.What drives the price of gold can be confusing and conflicting. While other commodities are mostly driven by supply and demand, gold is often affected by the psychological effects of economic downturns. Gold prices are affected by numerous economic factors such as: • Value of the U.S. dollar Numerous factors influence gold pricing, so no one person or organization is fully responsible for setting prices. However, the London Bullion Market Association (LBMA) publishes gold prices twice a day via the ICE Benchmark Administration (IBA). The IBA consists of multiple banks, an oversight committee and a panel of internal and external chair members. The IBA sets gold spot prices and gold fixed prices based on supply and demand as well as the gold futures derivative markets. If you do want to sell your gold, you can sell to a variety of buyers, including precious metals dealers, refiners, coin dealers, and jewelry makers. Research potential buyers and compare prices before selling to ensure you receive the best possible price.The amount of market value you can get depends on several factors: • Quality and Purity: The value of gold is determined by its weight and purity. Higher-quality, purer gold is worth more than lower-quality, less pure gold. A gold prospector will typically have their gold assayed to determine its quality and purity.

Tuesday, October 17 2023

In the words of Tom Massie, son of the late George "Buzzard" Massie who founded Gold Prospectors Association of America... "my favorite way of prospecting is the way that gets me gold." Suction dredging with a wetsuit can be quite lucrative— not only from the material you suck up but there's also the chance of picking SIZES OF GOLD:

Wednesday, March 29 2023

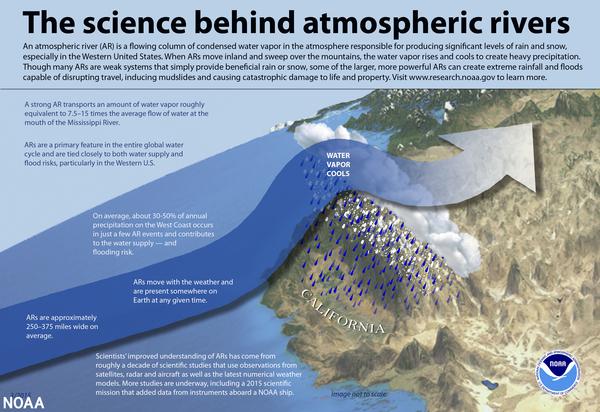

Did you know that “bad” weather can be really GOOD for gold prospectors? Of course no one ever hopes that Mother Nature causes catastrophic loss of life and property, but the ups and downs of weather events in any gold-bearing area are something to take advantage of. Nature can help all of us in our quest for the shiny stuff— especially in light of recent atmospheric rivers causing flooding and lots of snow in California, eastern Idaho, northeast Utah, northwest Colorado, the Cacade Ranges, portions of the northern and central Rockies, and portions of Arizona and Nevada.

How does this help you get more gold? Primarily, multiple weather events cause large amounts of gold to move and replenish areas that already have been worked. And even when the atmospheric rivers die down, the higher than normal snowpack will cause water levels in rivers to flow well into the summer instead of drying up in late spring. Higher water levels extend your mining season, and allow you to run high-production equipment such as highbankers and power sluices. Miners can also work stream bank deposits once the water recedes back to normal flows. Typical winter storms that regularly occur in gold-bearing areas usually do not create enough havoc to force substantial amounts of "new" gold into movement. However, when Mother Nature really goes to work as we’ve seen lately, a great deal of gold can be set free, creating a bonanza for gold hunters. Gold veins that have been hidden for decades suddenly can be exposed. Floods can also sweep gold out of abandoned mines and wash it downriver. Known gold digs can be washed out, trees uprooted, and the landscape eroded— all pluses for prospectors! When tons of rock, cobble, and boulders are swept downstream along bedrock during a huge storm, quite a bit of destruction occurs. Plants, weeds, and trees that normally grow along the river and gravel bars are washed away. And when a major storm or flood tears up large portions of a streambed, a fair amount of this newly-released gold, because of its weight, will be deposited along the riverbed and settle into cracks and crevices (hand dredges are an ideal tool in this situation).

Friday, September 30 2022

In an area either rumored or known to hold gold, where should you look first? The creek, the surrounding hills, washouts, or just where? The characteristics of the gold in that area will help you to know where to start. If the gold is flat and pounded, that indicates it’s been in the water a long time. If the gold is coarse and chunky, you know you’re getting closer to the source. When gold is smoother, stop and go back to the coarsest gold and start working upwards until you find the source.

Keep in mind that gold is gold, so there isn’t necessarily a better type of gold. Some is just easier to recover. There are only two types  of gold deposits. The first type is “lode” which is simply everything that is still in the matrix and in the ground, and the other is “placer” —or everything else. of gold deposits. The first type is “lode” which is simply everything that is still in the matrix and in the ground, and the other is “placer” —or everything else.Lode deposits refer to gold that is still locked within its original solid rock formation. This formation of gold generally starts as a vein in rock and is formed over millions of years. Since the gold is locked up in rock, and can be mixed with quartz, calcite, pyrite, and other minerals, lode gold usually requires specialized mining techniques to extract. Lode mining takes a lot more equipment and generally a lot more expense and is usually undertaken by large commercial operations instead of the average prospector. Placer gold is the gold that most prospectors are more familiar with. Placer gold isn’t really any different than lode gold. It is simply a concentration of that same gold that has eroded and traveled away from the vein. Since gold is very dense, it will move downhill much slower than the surrounding sediment. It tends to become concentrated on or near the surface of the lode, forming a “residual placer” close to the original bedrock exposure. Gold found downhill from the immediate outcrop above the nearest watercourse is called an “eluvial placer.” Once it reaches the nearest waterway and is transported by flowing water, the gold now is known as “alluvial placer.” The origin of the dust, flakes and nuggets found by panning and sluicing is usually from a vein up on a nearby mountain. Bench placers were originally stream placers. Benches are simply where the water used to be, maybe even millions of years ago. They are formed by erosion or geological events such as uplifts, earthquakes or plate drops that changed the stream flow. Some of the most profitable mining is performed on benches. Many benches are highly concentrated by the alluvial deposits that still feed them. Stream deposits are the last resting place for gold. Once the gold has been released from the lode, gravity and nature does the rest. And unless gold gets stranded on a bench, it will find its way to the water someday. It may take a million years, but it will get there. When deciding where to begin prospecting, most of the time you’ll want to start panning in a water way, or a wash in the desert where water once flowed. Then let the gold tell you where to go from there. When the gold gets coarse and ragged, start to move up, looking in reverse of how it got to the spot where you found it. In addition to panning and sluicing you may wish to upgrade your mining efforts with a highbanker or power sluice, dredge or trommel. Moving soft soil or river gravel is obviously much easier than breaking rock, but for small scale miners, a rock crusher can pulverize 2 or 3 inch sized rocks into powder in no time. Move more material faster— get more gold! Monday, February 21 2022

Depending on where you live and where you like to treasure hunt, you might still be buried under feet of snow. Or maybe spring has sprung and temperatures are on the rise there. No matter the weather, you probably have extra time on your hands this time of year, so put that time to good use. Even though you might not have been out in the field for the last few months, you can still be prospecting and getting prepared for a new season of gold hunting! In other words, use your downtime wisely, so you can hit the ground running as soon as Mother Nature allows. Inspect equipment. Did you properly clean and store your sluice and/or highbanker at the end of last season? In advance of heading Prepare your tools. Sharpen digging tools, picks, shovels, chisels and other specialty tools that require sharp edges. Now is also a good time to mark screwdrivers, magnets, crevice tools and other small implements with some bright colored paint. It’s amazing how easily tools can get “lost” in the dirt. A strip of bright yellow or red can help you more easily spot them. Double check the seals on snuffer bottles, hand dredges, and vials to make sure they’re tight. Pack your backpack or tool kit with everything necessary for a full day’s work. Maintain your metal detector. If your metal detector is still under warranty or giving hints of potential issues, the off-season is ideal for sending it to the manufacturer or taking it to an authorized repair shop to be fixed or tuned up. Check your rechargeable battery and make sure it is fully charged. Better yet, purchase a new battery as a back up. It’s also time to dust off the operator manual or search YouTube for “how to” videos pertaining to your brand and model. You’ll likely uncover some helpful tips and tricks, or learn a new recovery method. Is this the year to add a new coil or pinpointer? Now is a good time to consider upgrades and make those purchases earlier than you expect to use them. Do your research. The best kind of research brings together different forms of info from a multitude of sources. It is the info gleaned from combined sources that can help you to determine the best possible place to locate precious metal or gems— old mining district reports, mining history books, topo maps, aerial photos. Consult the Bureau of Land Management's LR2000 searchable database. The legacy system is undergoing upgrades; as the new systems is implemented, information will be easier to find. It can take a lot of time to research new areas, but when you find a new spot with good gold, it will be well worth your time and effort! It’s also a good idea to have alternate sites in mind just in case you cannot access your primary sites due to unforeseen closures.

Monday, November 16 2020

The use of water for grinding and milling has been in practice for thousands of years. From simple water wheels to inventors such as Water Flow. The easiest example of how water dynamics affect gold is the classic inside bend in a waterway. When stream flow is straight and velocities are at their highest, gold will be suspended in the flow. As a bend in the stream causes flow to begin slowing down, the heaviest gold begins to drop out because the water no longer has enough velocity to suspend the material. The stream continues to lose power as the bend length increases and smaller and smaller gold continues to be deposited until there is no longer any in suspension, or the remaining water flow and speed cannot carry it farther downstream. Water velocity and flow affect attempts at recovery in all capture devices in exactly the same way. Each piece of gold in classified material requires a certain flow and length of time to separate, drop out, and be captured based solely on its relative size and weight. If the velocity and flow are too great, the gold will remain suspended and will exit the machine regardless of machine length or method of recovery. This is why some miners are lured into a false sense of security just by using longer sluices. Improper water depth in the sluice can create additional problems in recovery. Methods of material collection have much less effect if the gold is suspended in the upper part of the water flow. Most sluices provide little or no material agitation to break up the classified material and provide the necessary change in flow that facilitates gold separation. Lack of agitation allows smaller pieces to be carried through the equipment. Classification. There is a direct relationship between material classification and water speed, which is often overlooked. It is common to classify for ease and speed of filling buckets rather than size of gold being targeted. Larger classification requires increased water speed to push the material through most recovery systems. The trade-off is forfeiting recovery of finer gold by increasing the length of drop time. This reduces the number of gold capture attempts and even machine effectiveness by having concentrations of larger material wedging into riffles, drops, etc. Running dry material requires the sluice to liquefy the material while it is passing through. Gold particles will suspend in the dry material, reducing the chance of capture. Many miners use a scoop and drop their material into the machine in large clumps. This also allows particles to suspend instead of being processed. Material should always be wet prior to processing, and material should be cast (sprinkled) side to side across the machine when using a scoop. Riffles. Some riffle designs are actually not that ideal for gold recovery. Some sluice riffles are evenly spaced, making them too far apart to impart the “vortex” or reverse underflow. What actually happens is an up-and-down wave motion as the water travels down the sluice. The only “action” imparted is the same negative flow that happens when water flows over a rock or some other obstacle in a stream. Material suspended at the bottom of the flow is deposited as the water climbs over the riffle and slows. Material that is heavy enough and can no longer be suspended drops. The rest of the material remains in the flow and continues to be carried down (and possibly out of) the sluice. Flare. Most modern riffle sluices (standard and drop designs) are susceptible to improper setup angle, which can either clog the machine with material or blow it out completely. Either problem results in the loss of gold. Another big mistake in sluice design and operation is the “V” fallacy. The idea that channeling your water towards the center of the sluice using a wide-angle flare will increase its effectiveness and therefore increase gold recovery is false. On top of that, miners drop material into the center of the slick plate. This forces material into the center of the sluice, which is quickly overloaded by the volume of material and will cause the first series of riffles to lose their effectiveness. Remove the flare from your sluice to eliminate the center concentration and create an even flow across the machine. You can create a V-shaped wing dam with a short straight section in front of your sluice if you need increased water flow or speed. Casting your material across the width of the sluice will eliminate overloading of the riffles. Understanding how water height and speed changes your recovery can also make all the difference in boosting gold returns: Water height. Begin with the water flowing just above the riffles or drops. Run small amounts of material and watch as the dirt passes through the sluice. Notice how the material enters the riffles or droops. Be sure to use the correct method of casting material evenly from side to side. Gradually increase the water height until processing suffers. This will determine the minimum and maximum water height for your sluice or highbanker. Water velocity (speed). Set your sluice water height for max processing and a fairly fast flow, then gradually reduce water speed as you process small amounts of material. You may have to adjust your sluice to maintain proper water height through this process. Note how changes in water speed decrease the quality of material processing. Spend some time exploring water dynamics. Introduce only one variable at a time, and verify how your gold recovery is affected before moving on. No doubt, with a little more understanding and experimentation, you’ll recover more gold with your sluice! Tuesday, June 23 2020

Ocean beaches can be compared to the Mother Lode. Why? Because you can find GOLD on many by mining with a highbanker, and by searching with a metal detector. How lucky is that?! TWO ways to find gold at the same location! Think about it, who hasn’t lost a ring or coins at the beach? Whether you prefer recovering gold by swinging a detector or shoveling into a high banker, your chances of both are higher by visiting a beach this summer that is located in a gold-bearing area. A side benefit is that you’re enjoying the nice weather while it lasts while mining the beaches in different ways. Beach Mining with a Highbanker When you consider the advantages of beach mining with a highbanker— easy access in all seasons, no classifying material down to size, no digging in heavy cobbles and moving boulders, no worries about rattlesnakes or poison oak— the idea is very appealing. Of course any new environment means there will be a learning curve. Recovering 100 mesh gold from the beach requires a little extra attention to detail to prevent loss, so you’ll need to readjust your equipment and process. Don’t expect chunky nuggets; you’re going for the flour gold here. High tide, not your watch, will dictate your schedule. The general principles you already know are the same, but also keep these tips in mind. • Slow down. Expect to process about 10 gallons of material an hour. If you try to feed a highbanker faster or use bigger scoops you will likely lose gold. The most efficient way to locate the paying black sand layers is to use a post hole digger or earth auger. The pay layer is usually right on top of a golden brown sand layer that pushes up into the black or blue sand. Frequent storms can remove the light sands and reconcentrate the black sands. • Use about 25% of the water you would normally use. You may need to modify your spray bar to compensate for less water volume so you aren’t fighting foam and bubbles. • The beach is a level playing field—literally, so tip your box to a 9-degree angle and go from there. Most beach miners use battery-powered bilge pumps to run their beach sluices. A small gas-powered pump also will work. A Gold Cube is also an excellent piece of recovery equipment to concentrate beach material, then run it through a Blue Bowl. • Do frequent clean-ups. Beach Mining with a Metal Detector Water and sunscreen have a sneaky way of slipping rings from fingers of swimmers and sunbathers, making beaches a lucrative location for metal detecting. There are actually several similarities between beach hunting for jewelry and hunting for gold in the rivers. At the beach, stuff that is lost in the upper sand areas make their way down into the surf during large storm events just like gold is washed downstream in the same storms. You can find an occasional nugget above a river in gold country, but you’re going to make your best finds when you locate the pay streak where nature has concentrated the gold. The same is true of the beaches. You will find that the surf sorts out materials, and when you are really lucky, you can identify a pay streak. In a river, the gold pay streaks follow the downstream flow of the river, but on the beach the pay streak will typically run horizontal across the beach. After items have been in the sand/surf for some time, the wave and current action tend to sort thing by weight and density. The pull tabs will be in a certain line, the lighter coins further down towards the deeper water, and when you start detecting fishing weights, you are likely nearing a pay streak. That is where you are most likely to strike gold— as in gold rings, bracelets, pendants, etc. Wet sandy areas are particularly lucrative for detectorists. The reason for this is that beach-goers first congregate at the "towel line" and then migrate to wet sand. The "towel line" is an invisible area where the majority of people plop down their towels and coolers and umbrellas. At the towel line, sunbathers slather on slippery sunblock and tanning oil that acts like a lubricant and lessens friction. After baking in the sun for a while, they will need to go into the water to cool off a bit, which is where the body's natural reaction to cold is to shrivel up. Less friction + shrinkage = rings in the wet sand you can find with your metal detector! In all types of beach hunting, the discrimination must be kept very low, eliminating only small iron (bobby pins and nails). Aluminum pull tabs and tin foil should not be discriminated or you will lose some gold and/or platinum rings as well. Some beach hunters operate with zero discrimination and dig everything. Use of a sand scoop makes target recovery fast and easy. It’s important to realize that most gold rings will read in the “middle” tones (above iron but below coins). If you’ve ever hunted the beach you have no doubt found your share of unwanted nails and other litter. To solve this, lace a rare earth magnet in the scoop to quickly capture those small, annoying iron targets. If you’re going to hunt the salt beach areas, you’ll want to get a heavy duty plastic scoop. A steel scoop will rust fairly quickly in those harsh conditions. If you intend to hunt IN the water, of course you will need a waterproof metal detector and waterproof headphones — one that can handle salt water mineralization. There are some good pulse induction machines that work extremely well in salt conditions. Very shallow water is no problem but when you hunt waist deep water and deeper you should consider a mask and snorkel. If possible, hunt at low tide. That way you can get further out and hunt where other detectorists might not have gone. Plus, the surf tends to pull things down the beach and out into deeper water.

Saturday, May 02 2020

Researching new areas in which to prospect for gold, gems, or whatever you are seeking can be a lot of work, but since we’re now

Monday, October 01 2018

A highbanker, sometimes called a power sluice, is a very flexible and efficient piece of equipment when you’re gold mining in areas with a good amount of water. Their main use is to allow you to pump the water to the gravels rather than carrying heavy buckets of gravel to the water. The optimal place to use a high banker is a location along a river where there are lots of bench gravels that have been left Hopper: The feed box contains a grizzly screen with a water spray bar. The water is normally sprayed from simple plastic pipes with a series of small holes drilled into them. A water valve located ahead of the spray pipe controls the amount of water flow going into the feed box sprays. A series of rods are arranged to make a slat-type screen (called a grizzly) that allows water and smaller material to fall through and go down into the sluice box. The large rocks that are caught by the grizzly are washed with the spray and then rejected. The slats should be set on an angle so that most of the larger gravel will slide off the slats by the pull of gravity without you needing to push them off by hand. Some rocks may hang up, but for the most part, they will slide off on their own. The spray water comes out under a lot of pressure and washes any loose sand or clay into the sluice and also provides part of the water needed to move material through the sluicebox area. Sluice: High bankers utilize a normal sluice to recover the gold from the gravels, and the operation of the sluice box portion of a high banker is basically the same as that of a hand or stream sluice. With a highbanker, the water is supplied by a pump rather than the flowing water of a stream. The matting and miners moss underneath the sluice’s riffles are the same. Gold flakes get caught in the riffles and moss the very same way as it does in a hand sluice. A nice back-saving bonus on a high banker is that it will be on legs, so you can operate it on any terrain. A normal hand sluice lays on the bottom of a streambed. Pump: The centrifugal type pump should be set near the water as it is more efficient to pump water uphill to the sluice than to suck it up to the pump. This is only important where there is a lot of vertical distance between the pump and the sluice. If there is less than 10 feet of vertical distance, it does not matter much. Pumps can be set up quite a distance away horizontally from the sluice. It will work so long as there is sufficient water at the source where the pump is located. Vertical distance is more of a problem than horizontal distance; 30-40 feet is the maximum vertical climb for most pumps. The standard lay flat type of hose is used to carry the water up to the feed hopper. Be sure to have enough hose and some extra in case you spring a leak! Remember to position the pump so that you aren’t breathing motor exhaust fumes all day! The big advantage of a highbanker is working materials that are found in a location away from a river, like benches and other isolated patches of gravel. Moving the water to the sluice with a pump saves you from carrying the material down to the stream. The only disadvantage to highbanking for gold might be that it’s more equipment to pack around than just your usual digging equipment. It would be wise to test your ground before hauling in your high banker. Testing will indicate if there is enough gold in the gravels to warrant bringing in more than a hand sluice. If you have at least an amount of gravel that represents a full day of digging and sluicing, bring in a highbanker. The adjustment of a high banker is much less than the steep slope you usually would use with a hand sluice. Adjust the water flow to the minimum flow rate that it takes to get all the rocks that fall through the screen to keep moving down the sluice box section. If rocks or gravel hang up and bury the sluice, you need more water and perhaps a steeper box angle to wash that stuff away. The height of the feed box is another important adjustment. You want it low to allow you an ease of feeding in the material. If too high, you will hurt your back lifting heavy shovels full of gravel. Too low and you may be constantly sweeping away tailings at the back of the sluice. The feed box itself should be adjusted to ensure the angle of the slat screen rods (the grizzly) allow the gravel to be well washed before it moves out as waste. This is because a lot of small gold adheres too the larger cobbles. If rocks and cobbles just roll through without getting a thorough washing, you will be losing gold. The rejection of the large oversize rocks is important as it lets your sluice to a better job. If those bigger rocks make it into the sluice, you’ll be getting much worse recovery of fine gold. Be sure the foot valve or strainer on the intake hose is clear and able to deliver a full water flow. Sometimes the foot valve can get clogged with leaves or other debris. A blocked or partially obstructed foot-valve won’t allow the high banker to operate properly. For environmental reasons, it is a good idea to have your water drain into a pond or pit that is not directly connected to the stream. This is so that the clay and mud can settle out, otherwise make sure there are no legal issues of putting that mud back into a flowing stream. Some models of highbankers can also be run as a dredge. These highbanker/dredge combos can save you money, offer flexibility, but are also a bit of a compromise since the dredge portion is generally small. Combo units will be equipped with a suction nozzle type of intake. This design is best for working small shallow streams and tributaries. These systems are designed to be set up alongside the stream edge and have adjustable legs rather than float systems that you’d normally see on a larger suction dredge. With a suction nozzle and more hoses, the combo unit will operate as a suction dredge, picking up material from underwater crevices and delivering it to the sluice. Highbanker/dredge combos also can be ideal for working in and around ponds in old hydraulic mining pits. The next time you are out in the field, consider if a highbanker or power sluice can help you get more gold. To determine if the answer is yes, ask yourself these questions: Where is the nearest water? Can I shovel directly from the diggings into the feed hopper? Can I set it up to allow gravity to do a lot of the tailings clearing work? Where will the pump go? With a little thought and planning, you’ll be able to decide if highbanking for gold will increase your productivity. In most cases it will. Move more dirt, get more gold! Good luck! Wednesday, June 14 2017

Fun and exercise are two great reasons to go gold prospecting, but you might as well make some money while you're at it, right? The best way to do that is to increase production rates. Assuming you are mining on a known gold-bearing claim or waterway, volume is the key to your success!

A dredge or highbanker/suction dredge combo is the next step up. A dredge uses a gas motor to generate the suction that will load and transport the material to the sluice, which greatly increases volume, as well as allows you to reach gravel on the river bottom that would otherwise be inaccessible (unless the river is seasonal or there is a prolonged drought). The more material a dredger can push across the riffles, the more gold can be recovered. An additional benefit to dredging is that it also allows you to clean gold out of all the cracks and crevices in the bedrock. A shovel just cannot do that. The size of the dredge intake nozzle is the most important factor in how much material a dredge can process, but it is not a direct one-to-one relationship. For example, a 5 inch dredge will not move twice the material that a 2.5 inch dredge can move. It actually can move much more. The surface of the hose is figured in square Beyond dredges or highbanker/suction dredge combos, you can get into some professional mining set-ups that use trommels and jigs and shaker tables and earth moving equipment. Every deposit is different, varying in size and grade and structure. Environmental conditions and access will dictate mining methods and knowing the rock types and size of the gravel is critical in determining which equipment will work best for increasing your production. Finding a suitable deposit to mine and finding a way to work it economically— to justify your time and expense— is the first step. Then choose the right equipment to increase your recovery rate and speed of recovery and make more money. Good luck! Saturday, July 02 2016

Although there are many variables that go into catching gold in a sluice, perhaps properly “tuning” your sluice is the most critical. A few months ago, Steven “Doc” Vetter, owner of Gold Hog brand mats, wrote an interesting article for Gold Prospector Magazine that focused on a few key factors that all miners should pay attention to. The following ideas from his article are all about achieving the proper tuning exchange, meaning letting the junk flow out, or be worked out by exchange zones, and holding the stuff you do want—gold. A well-tuned sluice will have heavy gold concentrations up top, medium gold in the middle, and trace gold near the end Hydraulic Equivalence: By definition, “hydraulically equivalent” (HE) refers to particles of varying size, shape and density that fall out of a water flow and deposit in the same area. While quartz rock and gold vary greatly in specific density, you can make them collect in the same place by making the quartz rock bigger and rounder. A 2 inch quartz rock and a 1 mm sphere of gold will fall through water and deposit in about the same place— making them hydraulically equivalent (HE). An opposite example is a .25 inch round piece of gold and a .25 inch round piece of quartz. The gold will sink through the water and likely land straight down. The quartz rock, however, will not fall as fast and will be pushed several feet away before it settles. These two items are not HE. The shape of the gold has a big influence on its HE. Flat things move more easily than spheres when either moving water or air is introduced. HE is a huge factor in gold mining and is often the main reason for classifying material to a certain size— the theory being if everything is about the same size, the heaviest material will stay in the sluice. When you slow down a sluice, you start to have a traffic jam. Things that are HE all want to gather in the same deposit zone and you start to gather/open the window for more non-gold particles to pile up and that’s not good. Incremental Processing: A great analogy of how this principle works is to picture a city bus. Imagine a rule where all passengers must enter through the front and must exit through the back. As they enter, passengers must fill the seats in the front of the bus first. Every time the bus makes a stop (you shoveling dirt into the hopper of your highbanker or sluice), the first few rows fill up quickly and remain full for a short period of time. As a new passenger (each new shovel full of material) gets on and finds the front seats taken, he must move further down the bus (sluice). The result is a bunch of folks all competing for the same seats up front and when there are no seats up front, they must take the next available one. If all the seats get full, a passenger (your paydirt) never even gets to sit down and exits the bus (sluice) without ever sitting (collecting in the riffles). As the working zones in your sluice fill up, slurry material will move down to the next zone before it settles there. During times of heavy loading, the first percentage of your sluice will load up heavy and take some time to exchange out. That means gold will keep traveling until it finds an “empty seat.” If you load too heavy or have too short of a sluice, you’ll have gold flowing over holding zones that are busy working and exchanging. It may take an exchange center (vortex) 3 or 5 seconds to fully process down material and exchange out non-gold and heavies. Fine Tuning: Because of the principles of Hydraulic Equivalence and Incremental Processing, you may have realized that slowing down a sluice can really cause problems and loss of gold. How do you know if your sluice is running too fast or too slow? Experiment! Of course doing so is a little scary because the #1 fear of most gold miners is losing gold, and quite honestly, until your sluice is fine tuned, that just might happen. To avoid losing gold, most miners start running their sluice at the “normal” or widely accepted pitch of 1 inch per foot. But this is just a starting point. If you see gold in your tailings, your first thought is probably to slow it down so you aren’t blowing gold out of the sluice. But perhaps that’s not the cause at all. Perhaps it’s because gold doesn’t have a place to sink down into and hide in your sluice. Experiment by running way too fast, say at a 15-degree pitch. Then take it to 13 degrees, then go down to 12.5. Keep adjusting until you find an acceptable capture rate for the size of gold you want to hold. Lose your fear of losing gold through testing and experimentation. Not only will you fine tune your sluice, but you’ll also get a great education. Good luck! Tuesday, December 01 2015

With the weather turning colder, you might think you're done prospecting 'til next summer, but you don't have to be! Even if you're not a regular snowbird heading to a warmer climate for the next few months, Gold mining in the desert is especially enjoyable if you're not into crowds— the desert can be delightfully smog free and people free in the winter. Experts say there is just as much gold waiting to be taken out of the desert as there is commonly found in streams and rivers. Why? Well, throughout history the desert mines just never got the publicity that wet places like California's Mother Lode did, so fewer prospectors went there. Plus, back in the day, mining used to be harder in dry conditions. Luckily that's no longer true if you have the right equipment.

• Metal detecting is another great way to hunt for gold in the desert. Gold detectors are not necessarily higher in cost, but they are built with a higher sensitivity to detecting gold nuggets, and have better ground balancing and • A bonus of prospecting in the desert is the abundance of interesting rocks. You can find many unusual rocks and semi-precious gems such as tourmaline, turquoise, agate, jasper, and more. Lapidary shops can cut and polish the rocks for you, or buy your own rock tumbler and lapidary tools and learn a new hobby. This winter, consider extending your gold-getting season with a prospecting trip to a sunnier, warmer state. Good luck and have fun! Sunday, August 30 2015

When you consider the advantages of beach mining with a highbanker— easy access in all seasons, no • Good luck and have fun! Monday, November 05 2012

Drywashers are like highbankers, but they do not use water, making them excellent tools for recovering gold from dry material in desert areas. A dry washer is basically designed to be a waterless sluice. It separates gold from sand and other waste material with pulsations of air, vibrations, and static electricity instead of running water.  The top portion of a drywasher is called a hopper and consists of a box covered with wire screen. The screen is called a "grizzly." Dry gold-bearing material is fed onto the grizzly, which is mounted at a fairly steep angle. Thinner material, such as dirt and small gravel, falls through the grizzly screen and into the hopper. Larger material, such as rocks and sticks, roll off the grizzly and back onto the ground. Material from the hopper is then fed by gravity into the riffle tray below (looks like a sluice box), through an opening in the bottom of the hopper. Friday, June 01 2012

A highbanker is basically a sluice box with mobility and added height. It is mounted on a 4-legged stand that gives the sluice box the correct slope. Instead of being put right in the creek like a sluice, an engine with a water pump and some hoses transports the water up from the stream into the highbanker. Highbankers are also called power sluices. It is a self-contained unit with many uses— prospecting, sampling, and concentrate clean up.

In general, a highbanker or power sluice is  extremely efficient at trapping gold, including very fine or "flour" gold. The biggest benefit of having this piece of gold prospecting equipment is the ability to process gold-bearing gravels located a distance away from a water source— in other words, you get to bring the water to the gravel, not the gravel to the water! You can purchase a highbanker with a pump/motor and all hoses and fittings included, or you can buy those items separately. extremely efficient at trapping gold, including very fine or "flour" gold. The biggest benefit of having this piece of gold prospecting equipment is the ability to process gold-bearing gravels located a distance away from a water source— in other words, you get to bring the water to the gravel, not the gravel to the water! You can purchase a highbanker with a pump/motor and all hoses and fittings included, or you can buy those items separately.To run a highbanker, you need a system to pump water to it. Highbanker pumps can be either electric (12 volt battery) or gas driven. Some highbankers are also designed and constructed to re-circulate water so they can be employed in situations where little water is available. Keep in mind that the pumps deliver less water as your equipment location is moved uphill. Pumping uphill increases the resistance on the pump, and as you move uphill, eventually there is a point where the pump will not provide sufficient water to run the high banker. The slope on the highbanker usually ranges from about three to four inches per foot. Article continued here... |

|

Nugget of News Blog |

of high inflation, market volatility and geopolitical uncertainty. Gold is a finite resource, and therefore increases in value over time. Knowing this, many investors turn to the precious metal in an effort to protect their money. And those holding it in their portfolios were rewarded in December 2023 when the price of gold hit an all-time high of $2,135 per ounce! Analysts say that record price was driven largely by a weak U.S. dollar and expectations the Fed will begin lowering rates.

of high inflation, market volatility and geopolitical uncertainty. Gold is a finite resource, and therefore increases in value over time. Knowing this, many investors turn to the precious metal in an effort to protect their money. And those holding it in their portfolios were rewarded in December 2023 when the price of gold hit an all-time high of $2,135 per ounce! Analysts say that record price was driven largely by a weak U.S. dollar and expectations the Fed will begin lowering rates.  nuggets out of a crack in the bedrock.

nuggets out of a crack in the bedrock.  Atmospheric rivers are large, narrow sections of the earth's atmosphere that carry moisture from the earth's tropics near the equator to the poles. On average, the earth has four to five active atmospheric rivers at any time. A vast majority of atmospheric rivers happen in the fall and winter. The northern Pacific Coast receives the bulk of activity in the fall, and the California coast receives more in the winter. Since December 2022, the U.S. West has been slammed with back-to-back-to-back atmospheric rivers. These events provide as much as half of the region’s annual precipitation, bringing much-needed water to parched lands and adding to the snowpack in the high mountains. This year’s storms have done a lot to restore the landscape drought and is “greening up” the landscape and refilling many smaller reservoirs.

Atmospheric rivers are large, narrow sections of the earth's atmosphere that carry moisture from the earth's tropics near the equator to the poles. On average, the earth has four to five active atmospheric rivers at any time. A vast majority of atmospheric rivers happen in the fall and winter. The northern Pacific Coast receives the bulk of activity in the fall, and the California coast receives more in the winter. Since December 2022, the U.S. West has been slammed with back-to-back-to-back atmospheric rivers. These events provide as much as half of the region’s annual precipitation, bringing much-needed water to parched lands and adding to the snowpack in the high mountains. This year’s storms have done a lot to restore the landscape drought and is “greening up” the landscape and refilling many smaller reservoirs.